Special edition: Track & Trace

Lascom updates CPG software to edit product specifications prior to INCO

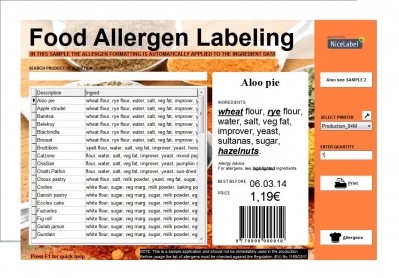

INCO requires 12 mandatory statements on product labeling; including name, ingredient list, nutrition facts and additional information such as ‘protective atmosphere package’ and ‘sweeteners addition’.

Nutritional values

Jean-Louis Henriot, chairman, Lascom PLM told FoodProductionDaily.com the latest version of CPG software will better assist the food industry and food service manufacturers to create labeling in compliance with the INCO regulation because they can edit product specifications (nutritional values, allergens, etc.).

“CPG offers functionalities to better manage data and documents attached to products in a single place. A product is not only a formula and packaging. Each product has specific regulation, certification and labeling regarding the countries it is sold to,” he said.

“A PLM gathers all these details, then while referring to a specific product, users benefit from the whole information about it. For instance, gluten free certification or halal approval by an external body or audit made about it, previous claims, versions, various labeling and regulation depending on the country of production, or of sales.”

The company HQ is based in Paris with three offices in Strasbourg, Saint Etienne and Toulouse and a US branch in San Diego, US.

Customers include Maple Lodge, Bolthouse, Stalaven, Servair, Materne, Yoplait, Lactalis, LDC, Agapes, Brossard and Frial.

Henriot added CPG features include; a formulation tool to update formula or create ones. It also automates nutritional values calculation, ingredients list editing, labeling creation and any other technical document update.

Define & organise tasks

A complaint management tool to better handle suppliers’ non-compliance and customers’ complaints; a supplier portal to transfer product specifications input and responsibilities regarding raw material; a task manager module to define and organize tasks and alerts in a project and a dashboard module to draw charts and analyze on-going activity.

“PLM consists of software providing a simple answer to complex problems. Through my experience, I noticed it is difficult for companies to manage products, projects and programs properly due to information complexity. For instance, a single ingredient change has many impacts on packaging, risks, allergen notice and price,” he said.

“There are many top trends booming in the food industry such as: ancient grains, mini format, indulgent product, more natural tendency, spicy taste, nostalgic and vintage graphic design on packs.

“With dedicated apps, consumers will shortly be able to know if products fit their needs, taste and health requirements. They will adapt their consumption to their ideal diet.

“Growing markets are Europe, US, Canada and Australia. In these countries, consumers’ expectations are high, competition is hard and regulations are complex.”