Scottish start-up turns to ‘food of the future’ seaweed to launch methylcellulose replacement

Methylcellulose is an ingredient in plant-based product formulation that has attracted negative attention. Used by high-profile brands like Impossible Foods and Beyond Meat, methylcellulose, or E461, provides attractive gelling and emulsifying properties that boost juiciness and hold plant-based burgers together as they cook. As plant-based proteins have low water retention capacity and can’t bind, hydrocolloids like methylcellulose are a necessity to achieve the desired end product.

But as a synthetic ingredient modified from cellulose, methylcellulose isn’t something that consumers have in their kitchen cupboards and is therefore often held up as evidence of the ‘ultra-processed’ nature of plant-based meat analogues. Moreover, inclusion in a formulation can actually add further complexity to the ingredient list.

The race is therefore on to address this problem and find alternatives. Scotland-based company OCEANIUM has just announced the launch of its first product, a clean-label one-to-one replacement for methylcellulose called OCEAN HEALTH Fiber.

The company formed in 2018 seeking to make a host of products from seaweed such as innovative materials, food ingredients and natural bioactive ingredients for health and cosmetics.

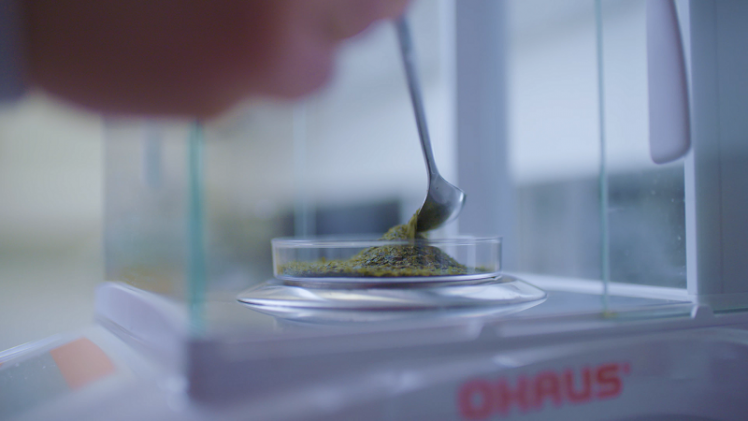

Its food ingredient is made from the fibre and proteins from sugar kelp sourced from farms around the world. “It's a natural mixture of alginates and cellulose and it's essentially the residue after we've refined the seaweed to remove high-value nutraceutical components,” explained OCEANIUM Food Scientist Iain Moore. “Because the refining process uses only green chemistry [the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances] it doesn't significantly affect the composition or the functional properties of this residual seaweed fibre.”

The ingredient’s greeny/brown colour suits meat analogues, he added. “In a burger it looks like cooked meat. When you add this you get a darker, slightly brown tinge to the burger and when cooked it gives a stronger colour in the finished product.”

Not solely a methylcellulose replacment

According to the company, the ingredient delivers improved moisture retention and water binding ability, as well as texture, viscosity, and gelling capabilities to finished products. It delivers equivalent functional properties and enhanced organoleptic characteristics that may reduce the need for added salt. It isn’t solely a methylcellulose replacement. It has a unique umami taste which can provide interesting flavour dimensions to a wide range of finished products. OCEANIUM’s in-house food scientists and B2B collaborators have already tested and proved its versatility in plant-based meats as well as several additional applications, including gluten-free breads and beverages.

“It is a unique product with great functionality due to its natural combination of insoluble and soluble polysaccharides,” added Moore. “This gives it a significant thickening effect at both low and high temperatures, similar to methylcellulose. It is also a very effective water binder which can increase the moistness of breads, particularly in gluten-free recipes.”

The company is targeting food manufacturers in Europe, the UK and US and expects the product will be declared on the ingredient list as ‘seaweed fibre’. It is yet to gain regulatory approval globally, however. It anticipates its US GRAS status will be complete in the first quarter of 2023 and hopes for European approval by the end of next year, though this will be longer if it's classified as a novel food.

Containing 69% dietary fibre, made up of both soluble and insoluble fibres, and a mixture of proteins and minerals, the company further hopes the ingredient may help address the lack of dietary fibre in most modern diets.

Seaweed can further support improved nutrition and diets as a source of plant-based protein and nutrients such as zinc, magnesium, and Vitamins A, B12, and K.

The company further envisages manufacturers making claims about the origins and the sustainability of the ingredient and its processing methods.

‘The most sustainable biomass on the planet’

OCEANIUM’s business model is based on proprietary biorefinery technology which extracts maximum value from sustainably farmed seaweed: a regenerative, resilient, and nutrient-rich marine plant and the ultimate sustainable biomass for plant-based food, nutraceuticals and materials markets.

“Overall, what we're trying to achieve is maximised utilisation of the seaweed biomass to minimise any waste,” explained Co-founder and CTO Charlie Bavington. “By converting the seaweed into a mixture of high demand ingredient products we are able to pay the price that the farmers need for their farmed seaweed thereby enabling the whole seaweed value chain, which is kind of nascent in the Western Hemisphere.”

An important part of OCEANIUM's mission, he said, is to facilitate seaweed farming at scale in places where it doesn't already happen. It's big in Asia, for example, but fairly non-existent in other parts of the world.

“We see farmed seaweed as the most sustainable biomass on the planet because of its environmental and societal benefits,” he said.

Sustainably farmed seaweed, he told us, provides jobs along rural coastal regions, mitigates eutrophication by absorbing nitrogen and phosphorous, increases biodiversity by protecting nursery grounds and seabeds. Seaweed farms do not need cleared land, fresh water, insecticide or fertilizer.

OCEANIUM has so far had supplies from across Europe including the UK, Norway, Faroe Islands and France. Small scale seaweed farms are also rapidly springing up on both coasts of North America. "Seaweed is going to be a very big part of our future food production and we're right at the beginning of that journey."

This emerging industry isn't without its challenges, however. “Overall, it's scale,” Bavington said. And although OCEANIUM’s product will be priced ‘competitively’ compared to methylcellulose, seaweed farmers face a host of cost and technological barriers as they try to scale up production and a lack of processing capacity doesn’t match the high demand for ingredients.

“We're all aware that consumers are demanding ingredients and food products with a clean label that deliver health benefits that also bring an impactful and fully traceable and provenance and sourcing story,” added OCEANIUM Business Development Director Marissa Nicolais. “While seaweed is still a relatively nascent ingredient in food products, more consumers are identifying it as a potential solution because of the diverse benefits that it can provide.”