Meet the start-up on a mission to solve the challenge of delivering more effective probiotics and bioactives

Microencapsulation is a protective technology used across a host of industries – from food and drink to pharma and agriculture – to deliver a myriad of otherwise sensitive and unstable ‘actives’, in a controlled manner.

Microencapsulation should isolate the ‘actives’ to ensure stability during shelf life, and safe delivery to the specific site of action in the body.

But there is no current microencapsulation method that is truly effective, believes Lisa Tammi Founder and CEO of Mello, which is focused initially on the microencapsulation of probiotics and after that, other bioactives.

“The problem is that industry is struggling to be able to deliver probiotic’s effectively and it's questionable as to just how stable these bioactives are by the time they are ingested,”she told FoodNavigator.

By way of illustration, the UK’s National Health Service currently tells those patients seeking advice about probiotics that it cannot “always be sure that the product actually contains the bacteria stated on the food label; that the product contains enough bacteria to have an effect; or that the bacteria are able to survive long enough to reach your gut”.

Proprietary technology ‘key’

Technology is one limiting factor currently preventing the efficacy of unstable, difficult to deliver ‘actives’, according to Tammi. Mello has therefore developed proprietary technology and is working on a ‘unique’ target-driven, controlled-release delivery.

The company claims the process can generate particles robust enough to fully enclose the inner bioactive or probiotic ingredient, withstand degradation and remain functionally effective, but small enough so as not to adversely impact mouthfeel.

Powering the beneficial potential of ‘actives’

“We’ve developed a proprietary 1 step, water-free process to generate a TrueCore particle at a micro size, using a lipid-based combination,” explained Tammi.

A TrueCore type particle differs from a typical matrix particle by having a shell around the ingredients, she explained. Matrix particles , by contrast, have no shell and therefore expose the ‘actives’ to heat, moisture and other elements which can compromise shelf life. and means at processing stage ‘you are already losing some of the bioavailability’, according to the CEO.

“Our technique is unique because we are developing a micro-sized TrueCore particle that isolates the active ingredient on the inside,” she said. “Additionally, we’ve developed a one-step, water-free process, so we are eliminating the fact that the conventional process can degrade the bioactive or probiotic ingredient at the processing stage. Our shell is hydrophobic as a lipid combination, so it's enabled to withstand degrading factors such as different pH levels and moisture. It’s also of a small micro size which means it can be added to a drink without negatively effecting the mouthfeel… If industry currently wants to create a TrueCore particle it needs to be done in more than one processing step which means that the particle can end up being 500-800 microns in size. Ours is around 100 microns.”

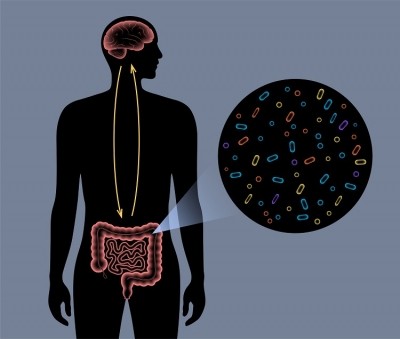

This fact is crucial for robustness, she stressed. “You take a bioactive or a probiotic: it needs to be released in a specific location in the body to be able to be functionally effective. But if the micro-encapsulation isn't robust enough it might disintegrate or expose the actives prematurely and the bioactives loose their functional effectiveness."

Through conversation with the industry, Mello has validated that its technology ‘has a clear competitive advantage and that it will fulfil an unmet industry need’, she told us.

“Nobody actually knows if the probiotics we are ingesting are working to their full potential or not,” she claimed. The competitive advantage of an effective delivery technology would therefore be significant. “There is a huge need to fill the gap for smart delivery especially with all these new bioactives that are being discovered and as consumers are looking for better and healthier food options.

“Another big problem is in NPD. if you can’t keep an ingredient stable it can bedifficult and costly to go through the NPD process. What we are told by industry is that some products are either abandoned because they can’t keep these actives stable or a product goes to market but it's still not optimised.”

So there's a lot of opportunity within product development. If you are able to stabilise products better, you can develop a much more effective consumer facing product.”

‘There are a lot of solutions that could potentially be developed for different players in the market’

Mello is seeking to license out its technology to manufacturers. "This is also a technology that can be customised to differnt bioactives,” revealed Tammi. For example, the company is about to test plant-based milks with a view to helping these products improve the bioavailability of B12 and omega 3 vitamins.

It is also looking to develop microencapsulation with a view to improving the nutritional quality of plant-based products. The recent innovation in plant-based food and drink for example has focused mostly on organoleptic properties in for example burger and nugget-like formats, rather than on nutrient density. There are therefore concerns that this could lead to health-related health issues in the future.

Enhancing nutritional profiles by incorporating exogenous ‘actives’ into plant-based alternatives is challenging, however, in part due to stability issues. The bioavailability of some nutrients in upcoming plant-based ingredients is questionable.

But enable the incorporation of bioavailable nutrition into plant-based food and drinks is a clear opportunity area for Mello. “An example of how powerful this technology could be is that Iceland has enough spirulina to potentially create protein efficiency for the whole of the Nordics. But there are some unstable compounds within the spirulina. No one knows yet if and how much protection the spirulina needs for it to go into foods and drink.”

Microencapsulation is also not just used to promote nutritional value but used to mask flavour and odours and to stop different ingredients inhibiting one another. Microencapsulation technology ultimately therefore allows food formulators to develop an array of ‘healthier, more diverse products’, believes Tammi. “I would like to create a platform where we can co-develop with industry,” she said. “There are a lot of solutions that could potentially be developed for different players in the market.”

Mello has also just received additional support through the accelerator BioInnovation Institute’s Venture House programme which will help its more pressing tasks of optimising and upscaling. “Mello’s technology could enable the food industry to do a lot of the things it current lacks,” a BII spokesperson told us.