Bringing the snacks industry up to date on acrylamide

Considered both genotoxic and carcinogenic, the snacks industry faces mounting pressure to implement strategies that reduce its formation without compromising taste, texture or overall product appeal. Balancing these demands poses a formidable challenge for manufacturers striving to ensure food safety and meet regulatory standards, while maintaining competitive market positions in a sector characterized by dynamic consumer preferences.

The European Snacks Association (ESA) plays a pivotal role in addressing concerns related to acrylamide. As a leading trade organization representing the interests of snack manufacturers across Europe, it actively collaborates with regulatory authorities, scientific communities and its member companies to disseminate research findings and best practices aimed at reducing acrylamide levels in snack products. This includes promoting the use of guidelines developed in conjunction with by the European Commission, which detail practical measures such as adjusting cooking temperatures, modifying ingredient formulations and employing alternative processing techniques.

By fostering a collaborative environment and providing educational resources, the ESA also helps its members stay compliant with evolving regulations and consumer expectations regarding food safety.

Bakery&Snacks caught up with scientific and regulatory affairs manager Andrew Curtis at the recent Snackex held in Stockholm, to run through his presentation on the of latest data from the sector.

“I think the industry widely knows about acrylamide,” Curtis told this site, but for those who need a refresher:

Acrylamide (AA) is a chemical that has been commercially produced since at least 1954; used in a wide variety of industrial applications.

To find out more

ACRYRED – a multi-disciplinary research and communication network on reducing acrylamide formation, involving the entire value chain from grains to consumer products – is hosting a conference on ‘Acrylamide and process formed contaminants: A supply chain approach’ in Brussels on September 4-5.

The event brings together scientific and policy experts who are interested in the breeding, processing and production implications of acrylamide formation in popular foods such as cereals, potatoes and coffee.

Confirmed speakers include: Frans Verstraete (European Commission), Benedikt Cramer (University of Münster), Manuel Coimbra (University of Aveiro), Andy Curtis (European Snacks Association), Franco Pedreschi (Pontificia Universidad Catolica de Chile), Friedrich Longin (University of Hohenheim), Christine Nowakowski (General Mills, Minneapolis), Jane Parker (University of Reading), among others.

It was reported for the first time in 2002 as a chemical that formed naturally in some starchy foods when they were cooked at high temperatures as part of the Maillard reaction.

The main precursors were quickly determined to be reducing sugars (fructose, glucose) and amino acids (in particular, asparagine), which are naturally present in ingredients like potatoes, wheat and coffee.

In potato chips, a link was identified between a daker color and higher acrylamide levels.

It created a big issue for sliced potato chips in particular, because of the (initially) high levels detected. This was related to variability amongst processes and in raw materials (tuber to tuber, region to region, variety to variety, season to season).

The last full assessment by the International Agency for Research on Cancer (IARC) (in 1994) classifies acrylamide as a ‘probable human carcinogen’ (Classification 2A). In April this year, the IARC Advisory Group on priorities for monographs during 2025-29 was published in Lancet Oncology, classifying AA as a high priority for re-evaluation.

The last assessment by the Joint FAO/WHO Expert Committee on Food Additives (in 2010) concluded that neurological effects are unlikely at the estimated average exposure. However, for a compound that is considered both genotoxic and carcinogenic, margins of exposure (MOE) indicate a health concern.

The European Food Safety Authority’s (EFSA) assessments (in 2015 and more recently in 2022) determined it to be a concern to public health based upon carcinogenic effect on animals and on levels of dietary exposure. While epidemiological associations have not demonstrated acrylamide to be a human carcinogen (human epidemiology is still seen as weak or at least inconsistent), the MOE indicate a concern for neoplastic effects (that is, cancers).

As a genotoxic carcinogen, no safe level could be determined.

The challenges

It’s difficult to set practicable maximum levels (MLs) due to the many variables (tuber to tuber, region to region, variety to variety, season to season). Typically, lower levels are recorded in the summer period when the potatoes are fresh from the field, with higher levels seen in potatoes from storage as a result of sugars accumulation, explained Curtis.

In December 2019, the European Commission issued a stakeholder consultation on revising existing BMLs for potato chips from potatoes and potato dough, potato-based crackers and potato-based savory snacks with a moisture content > 5% from 750 μg/kg to 700 μg/kg.

However, it also revised existing BLMS – from 400 μg/kg to 300 μg/kg – for crackers with the exception of potato based crackers’, which ESA believes creates potential confusion as conflicts with Commission guidance.

As such – and with no safe level determined – the ‘As Low As Reasonably Achievable’ (ALARA) approach has been adopted within the EU.

Several industry associations have stepped up with tools to help producers follow the ALARA approach.

In 2005, FoodDrinkEurope – with the support of the European Commission – first published its Acrylamide Toolbox in 2005. A revised version is expected out to be published later this year.

The FAO/WHO Codex Alimentarius ‘Code of Practice for the Reduction of Acrylamide in Foods’ was published in 2009. Like FoodDrinkEurope, Codex has announced that it is working on a revised version.

“India last year announced that they wanted to look at Codex again, which will bring us up to date with where we are with the FoodDrinkEurope Toolbox, which is also due to be revised,” said Curtis.

In 2016, the US Food and Drug Administration (FDA) developed a ‘Guidance for Industry’ that outlines strategies to help growers, manufacturers and foodservice operators reduce acrylamide in the food supply.

Data snapshot

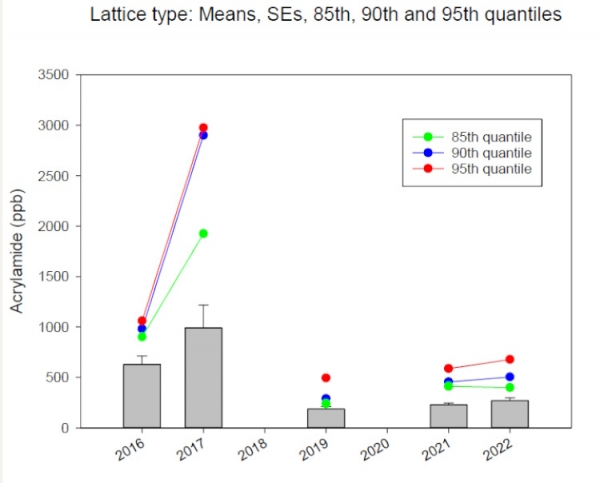

Curtis told us ESA annually collects data from its members – who are expected to regularly test their products – which is compiled and submitted to the European Food Safety Authority (EFSA). The results of this long-standing exercise demonstrates the success the industry is having in reducing levels over time by following the ALARA principle.

“It proves the success of the Toolbox approach in Europe and helped establish the basis for the EU Regulation,” said Curtis.

The latest data primarily covers sliced potato chips, with some data on potato sticks and lattice cut chips and dough-based snack products.

“Unfortunately, there’s not a huge amount of data on sticks and lattice cut chips. Overall, these products are not a big part of the market, and we’ve tried to separate them out in our analyses where possible. This is because, although they are a form of potato chip, they ’re different because of the surface to volume ratio, which could potentially have an influence on have higher acrylamide levels. Also, with standard potato chips, you can use a good scanning system to identify and eject defects. However, it’s a lot more challenging to do that with a stick or lattice product due to their size and shape.”

The same is true for data on sliced vegetable chips.

“There aren’t that many producers of vegetable chips in Europe and it’s a more challenging area in that you have more natural sugars that are present within these products. And unlike potatoes, which have had years of breeding for the specific purpose of making potato chips, the vegetables used are what’s available on the market at the time.”

The big set of data as always, is for sliced potato crisps.

“This year, we’ve submitted 9,700 or so data points for sliced potato chips.”

Added Curtis, “Steve Powers, a statistician we’ve worked up for a number of years, cleans up the data for us. The data we get from our members must be double checked to make sure it’s correct; that we’ve got the correct laboratory accreditation; the right correct value limits of quantification; or that the product is categorized correctly. But what we see year after year is that the macro trends remain the same: lower levels in the summer period when the potato is fresh from the field and higher levels when you’ve got to store potatoes.”

Powers, along with Prof Nigel Halford, has also co-authored three peer-reviewed papers based on ESA data on tracking the progress on reducing acrylamide levels in Europe.

In the revised version of FoodDrinkEurope Toolbox, Curtis said ESA hopes to expand the types of products listed.

“At the moment, we have solutions for potato chips and dough-based snacks, but in the updated version, we’ll look at sliced root vegetable chips as well and maybe one or two of the other products in the Commission Recommendation.

“The challenge will remain in how effective these tools can be in a real-life factory situation. The Toolbox typically lists research tools (ie, lab scale), development scale and commercial scale toolsm and whilst we see a lot of lab data, what’s on paper doesn’t always successfully multiply up to the large commercial scale. So, we’ll have to go back and relook at this.

“For instance, there’s been a lot of recent work on the addition of antioxidants to frying oils as a mitigation tool. But if you’ve got a large production line, turning over thousands of tons of product per hour, and you’re talking about putting a small amount of an additive into the frying oils: how effective will that actually be on this larger scale?

“One of the standouts about this industry is that everyone knows the issue and has been managing it very well. Everyone is keen to see what the latest results are, and we try to give as up-to-date data as we can. Obviously, these will inform the discussions we’ll have with the Commission and members going forward: so, whether we get maximum levels (MLs) at some point in the future, or whether it’s just revising the benchmark level (BMLs) for some products or new BMLs for other product categories, we need to have the best tools available to support those manufacturers achieve these values.”

Maximum vs benchmark levels

I asked Curtis if ESA expects the current EU elections to change the regulations?

“Whatever the Commission and Member States agree upon goes to Parliament and is usually endorsed. It’s therefore important that information about the challenges associated with AA mitigation are communicated to, and understood by, all parties involved in the regulatory process,” he said.

Challenges have in the past come from other third sector group sectors.

“A while back, a proposal was put forward for Maximum Levels for specific foods for infants and young children foods. This was proposed based upon the EFSA data, and the proposals had the backing of EU Member States experts. However, there was an intervention by interested parties within the NGO community who felt the levels weren’t challenging enough. They successfully lobbied parliamentarians, but the proposal was rejected.

“Whilst perhaps well intended, the intervention wasn’t a balanced assessment of the data. It demonstrated a lack of understanding of the complexities of the issue, and ultimately meant that Maximum Levels were not introduced for these products – which I’m sure wasn’t the intention of the NGOs.”

Safe Food Advocacy Europe (SAFE) is calling on the incoming European Parliament to implement stricter Maximum Levels, especially for products targeting infants and young children.

“SAFE is very disappointed by the lack of action by the European Commission since 2017 on this issue, as legally binding Maximum Levels of acrylamide have not yet been established,” the watchdog said in a statement.

It is advocating for a ML that is well below the proposed 50 μg/kg for baby foods, citing studies that indicate levels as low as 1 μg/kg are easily achievable.

“We believe that setting a higher ML than the current benchmark of 40 μg/kg could hinder efforts to reduce acrylamide content in these products.”

For biscuits marketed towards children, SAFE is calling for a ML that is significantly lower than the current benchmark of 150 μg/kg; and recommends reducing the BML for breakfast cereals targeting children under three-years-of-age.

It is also calling for regulating new categories, such as roasted nuts and veggie chips.

“Vegetable chips, for instance, were found to contain very high levels of acrylamide (as high as 3500 μg/kg) in various samples analysed by CVUA Stuttgart in 2023. Another 2024 study on acrylamide in foods in Germany also showed the measured acrylamide levels in vegetable crisps were twice as high as the benchmark level set by the European Commission for potato crisps (750 μg/kg).

“To make matters worse, there is a significant lack of consumer awareness regarding acrylamide, which prevents them from making informed choices when purchasing food and when preparing and cooking meals in ways that minimize acrylamide formation.”

As such, SAFE has launched an awareness campaign to educate the public on how to recognize acrylamide, while providing them with practical videos and tips to cook food at home in a safe manner, created in collaboration with SAFE member Associazione per lla sicurezza nutrizionale in cucuina.

However, admitted Curtis, “I’m not a fan of Maximum Levels. I think the approach the Toolbox takes – which is embedded in the current Commission regulation – is the right solution for such a highly complex issue one. If you look at data, it shows that – for our sector at least – it has worked and continues to work because there’s more flexibility for manufacturers.

“One of the big issues facing the Commission in revising Benchmark Levels, introducing new Benchmark Levels or even Maximum Levels, is how they’re going to better classify some categories. Take for example, the breakfast cereal or biscuit categories, which can have various multiple production methods for end products that can looks and or tastes very similar. There are equally many products that are produced in a very similar way but are quite distinct in their texture or appearance.

“The challenges arise because of the multiple different factory environments, different scales of production, different ingredients and even different national tastes. Are these actually all the same product? And is it ‘fair’ to group products under broad category headers with levels that some products might never be able to attain? I think the Benchmark Level approach has proven to been the right approach so far, and we’re hoping to see that being revised based on the data, pushing the industry to achieve more, but not breaking it in the process.

Added Curtis, “There’s also a huge technical implication for putting Maximum Levels in place. Even if you were able to put all the best practices in place, set up a hugely expensive testing system and implement a positive release system, you could still end up with lots of expensive product recalls. This would not be because of bad practice, but simply because we are dealing with natural variation and that always includes outliers. Raw materials are not always homogenous, and despite testing and controls, you may find that one tuber with higher sugar levels – maybe because of more stress in the field or in store – gets through the system and could give you an unexplainable higher reading.

“All varieties behave in different ways and react to different impacts as well. It could be stress in the field – excess water or heat – and then when it’s lifted and goes into store, it’s not stable. That could lead to a store breakdown, and you could have problems with the finished product as a result.

“So, you need to have these considerations in place and a Maximum Level wouldn’t allow you to do that. And of course, within our sector, you’ve got those peaks and troughs related to seasonality, which makes it incredibly difficult for any potato product to be managed. It must be looked at on a case-by-case basis.”

The post-CIPC challenge

In 2019, the sector lost the use of chlorpropham (CIPC), which was widely used to suppress sprouting in store potatoes and thereby reduce sugars accumulation. Its use was banned in the EU and UK over theoretical toxicity concerns, with sales prohibited from January 2020. There are, however, the obvious residues that can persist, prompting the EU and UK authorities to set temporary Maximum Residue Levels for CIPC (at a EFSA approved safe level rather than a default limit of detection) so these crops don’t go to waste.

According to Curtis, who is also director general of the UK Potato Processors Association, although several post-CIPC treatments have popped up, none are quite as “bullet proof” as CIPC, leading many store operators to upgrade their facilities or change the way they work. It’s unlikely any alternative is going to provide a completely straightforward swap for CIPC, meaning a multi-pronged approach to sprout suppression might be required.

“With limited time to familiarize themselves with the new actives, in the first year, there were some major losses in store and the quality of some potatoes did suffer,” he told this site.

There are currently four substances approved for instore sprout suppression in the UK and Europe. Three can be used for organic potatoes and are based on mint oil (traded by Juno under the BioxM brand), orange oil (sold as Argos by UPL) and ethylene (marketed as Restrain). The fourth, DMN (registered as 1,4SIGHT or DORMIR by DormFresh) is not currently suitable for use on organic potatoes.

Maleic hydrazide (marketed by UPL under the brand name Fazor) can also be applied infield to help discourage sprouting in stored potatoes by extending their dormancy period.

“These past two years, at least in Europe, have been quite challenging for growing potatoes,” said Curtis, adding “growers have adapted well and continue to learn year on year.”